Bernic

( number of products: 45 )Bernic is a Danish company that has been operating in the industry for over 40 years. The company was established in 1952, starting with the production of carbon microphones. In 1984, it entered the DIN rail enclosure market. From the beginning to this day, Bernic enclosures have been designed and manufactured in Denmark, thanks to which the manufacturer can provide EUR1 certification covering all goods and have full control over the supply chain.

Customization of Bernic DIN Enclosures

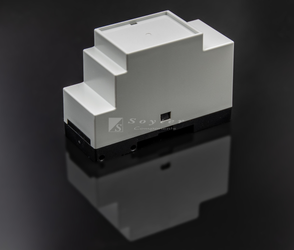

The manufacturer specializes in DIN rail enclosures made in accordance with the DIN 43 880 and DIN EN 50 022 standards, using high-quality Lexan 940 material and self-extinguishing Noryl V0 - in accordance with the standard UL 94 V0. It offers a diverse range of enclosures specifically designed to meet unique application requirements. The comprehensive and constantly evolving range of enclosures meets the needs of a wide range of industries, including industrial automation (meters, sensors, relays, etc.), heating and air conditioning, lighting control, building control systems and the rapidly growing electric vehicle charging industry.

The special features of Bernic enclosures are:

- snap assembly on DIN rails in accordance with the DIN EN 50 022 standard - 35 mm wide mounting rail

- modular sizes ranging from 1 to 15 in accordance with the DIN 43 880 standard - length of one module 17.5 mm, width approximately 45 mm

- a wide range of enclosure types differing in top design, with the same base, which allows for varied combinations to meet the specific requirements of projects while maintaining the design

- standard use of high-quality self-extinguishing material Lexan 940 (top of the housing) and Noryl V0 1550 (base of the structure) compliant with UL 94 V0

- easy and quick assembly of enclosure parts by snapping in without tools

The Danish company puts sustainable business development first, along with the quality and safety of protected electronics

"We know that our actions now will shape the future, therefore we continuously strive to become better and reduce our Co2 footprint. 90% of our enclosures are produced and assembled in Denmark to reduce transportation and Co2. The power that keeps the lights on and the machines running in our production and office facilities comes from the local source of renewable energy – Danish offshore wind turbines. The power is supplied by Ørsted and is CO2 neutral. we are also on a mission to end plastic waste, by offering our customers to take back enclosures end of life, to ensure they are recycled or disposed of in the proper way. Our goal is to carbon neutralize our remaining Co2 footprint by planting forest. In 2021 we planted more than 5000 trees on land we have purchased in Fredensborg, north of Copenhagen Denmark. we will continue looking into new initiatives that will lead us to a more social and ecological responsible business."

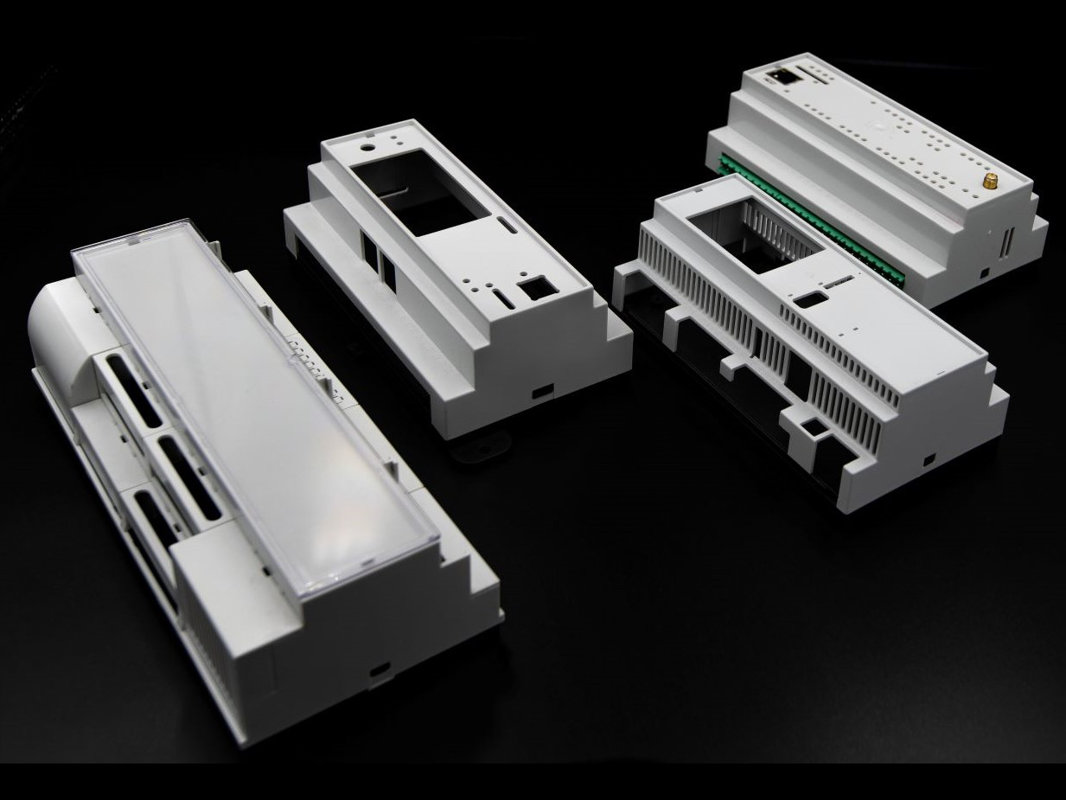

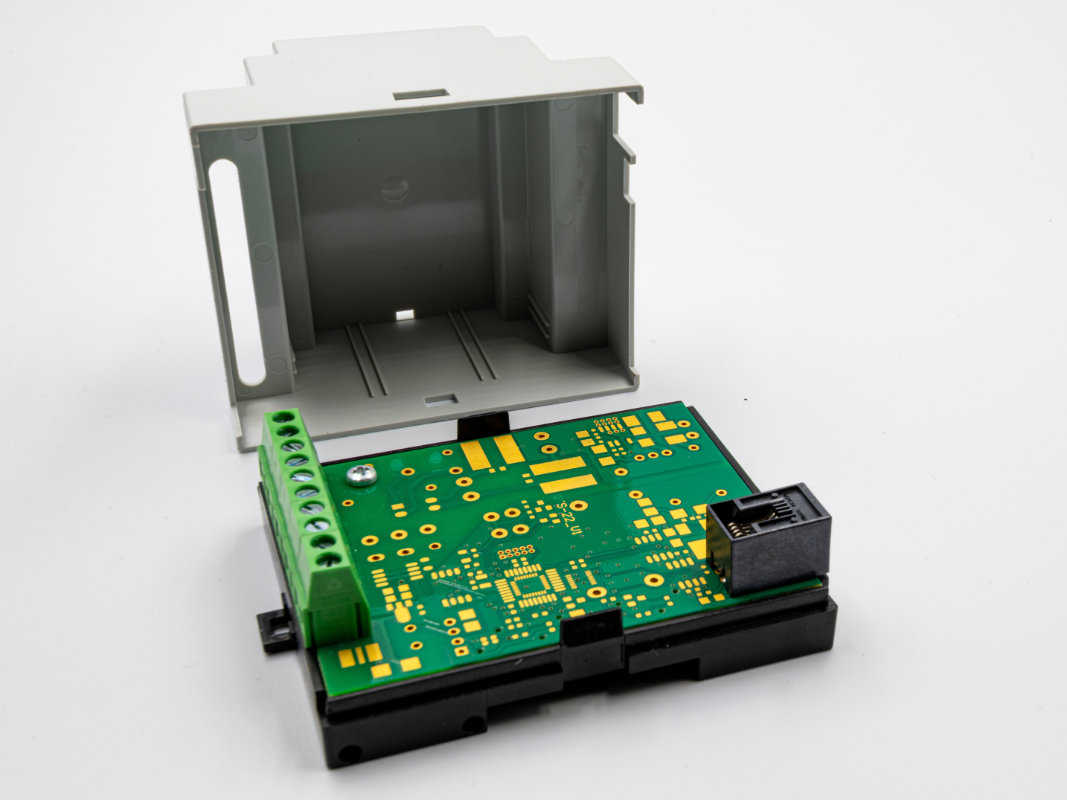

Example applications made by Soyter Components

Bernic Series 1570 High/low, 9 module enclosure (TOP - 497933571 + BASE - 4969021571)

- Product length in millimeters:

- Material:

- Modules:

- Norm:

- Type of cover:

- Ventilation:

Bernic Series 1570 High/low, 9 module enclosure (TOP - 497933570 + BASE - 4969021571)

- Product length in millimeters:

- Material:

- Modules:

- Norm:

- Type of cover:

- Ventilation:

Bernic Series 1570 High/low, 9 module enclosure (TOP - 497933572 + BASE - 4969021571)

- Product length in millimeters:

- Material:

- Modules:

- Norm:

- Type of cover:

- Ventilation:

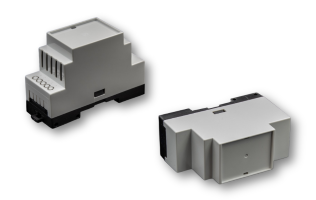

Bernic Series 350, 2 module enclosure (4969010352)

- Product length in millimeters:

- Material:

- Modules:

- Norm:

- Type of cover:

- Ventilation:

Bernic Series 350, 2 module enclosure (4969010358)

- Product length in millimeters:

- Material:

- Modules:

- Norm:

- Type of cover:

- Ventilation:

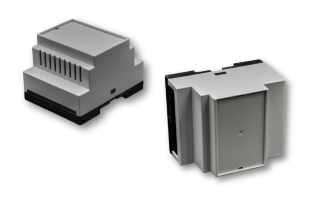

Bernic Series 520, 3 module enclosure (4969025252)

- Product length in millimeters:

- Material:

- Modules:

- Norm:

- Type of cover:

- Ventilation:

Bernic Series 700, 4 module enclosure (4969010705)

- Product length in millimeters:

- Material:

- Modules:

- Norm:

- Type of cover:

- Ventilation:

Bernic Series 1050 High Cube, 6 module enclosure (4979371050)

- Product length in millimeters:

- Material:

- Modules:

- Norm:

- Type of cover:

- Ventilation:

Bernic Series 700 High Cube, 4 module enclosure (4979370700)

- Product length in millimeters:

- Material:

- Modules:

- Norm:

- Type of cover:

- Ventilation:

Bernic Series 1050 High/low, 6 module enclosure (4979341050)

- Product length in millimeters:

- Material:

- Modules:

- Norm:

- Type of cover:

- Ventilation:

Bernic Series 1050 High/low, 6 module enclosure (4979341052)

- Product length in millimeters:

- Material:

- Modules:

- Norm:

- Type of cover:

- Ventilation:

Bernic Series 1050 High/low, 6 module enclosure (4979341051)

- Product length in millimeters:

- Material:

- Modules:

- Norm:

- Type of cover:

- Ventilation:

Bernic Series 700 High/low, 4 module enclosure (4979340700)

- Product length in millimeters:

- Material:

- Modules:

- Norm:

- Type of cover:

- Ventilation:

Bernic Series 700 High/low, 4 module enclosure (4979340701)

- Product length in millimeters:

- Material:

- Modules:

- Norm:

- Type of cover:

- Ventilation:

Bernic Series 700 High/low, 4 module enclosure (4979340702)

- Product length in millimeters:

- Material:

- Modules:

- Norm:

- Type of cover:

- Ventilation:

Bernic Series 350 High/low, 2 module enclosure (4979340350)

- Product length in millimeters:

- Material:

- Modules:

- Norm:

- Type of cover:

- Ventilation:

Bernic Series 350 High/low, 2 module enclosure (4979340352)

- Product length in millimeters:

- Material:

- Modules:

- Norm:

- Type of cover:

- Ventilation:

Bernic Series 350 High/low, 2 module enclosure (4979340351)

- Product length in millimeters:

- Material:

- Modules:

- Norm:

- Type of cover:

- Ventilation:

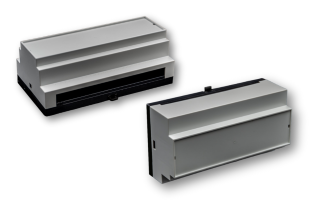

Bernic Series 2600, 15 module enclosure (4969012600)

- Product length in millimeters:

- Material:

- Modules:

- Norm:

- Type of cover:

- Ventilation:

Bernic Series 2600, 15 module enclosure (4969012602)

- Product length in millimeters:

- Material:

- Modules:

- Norm:

- Type of cover:

- Ventilation:

Bernic Series 2600, 15 module enclosure (4969012601)

- Product length in millimeters:

- Material:

- Modules:

- Norm:

- Type of cover:

- Ventilation:

Bernic Series 2100, 12 module enclosure (4969012100)

- Product length in millimeters:

- Material:

- Modules:

- Norm:

- Type of cover:

- Ventilation:

Bernic Series 2100, 12 module enclosure (4969012102)

- Product length in millimeters:

- Material:

- Modules:

- Norm:

- Type of cover:

- Ventilation:

Bernic Series 2100, 12 module enclosure (4969012101)

- Product length in millimeters:

- Material:

- Modules:

- Norm:

- Type of cover:

- Ventilation:

- 1

- 2